Back to product listing

Back to product listing

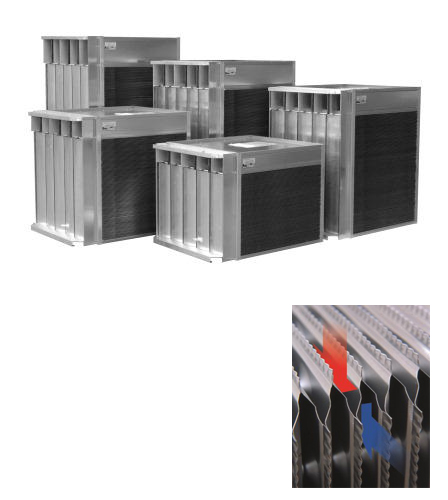

Plate heat exchangers for industry, Polybloc

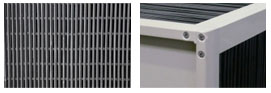

The POLYBLOC made from aluminum is resistant to a differential pressure up to 10‘000 Pa.

This extraordinary stability is achieved by the special construction of corrugated and dividing plates. The aluminum POLYBLOC is also available with epoxy coating for medium corrosive applications for example in indoor swimming pools.

For many high corrosive applications the Polypropylene

POLYBLOC is the right choice. For exhaust air from for example brine baths, galvanizing plants or laboratories the plate heat exchanger is usually made from PP. For especially aggressive media (e.g. chromic acid) the heat exchanger can also be produced in PVC. The deep drawn plates are sealed together and then additionally fixed by ultrasonic welding, which ensures constant high tightness.

The POLYBLOC made from stainless steel is resistant to differential pressure up to 10‘000 Pa. With the wide range of different plate spacing and sizes the requirements of the client can be fulfilled precisely.

The block made from 316Ti (1.4571) can be used at very high temperatures and with very corrosive flue gases. Depending on the demand on tightness and the choice of suitable sealings it can withstand temperatures of up to 600°C. In the main application for example by a recovery of process energy up to 250° C, the investment costs are paid back in a very short time by high energy savings.

For applications with very high demands on temperature and on tightness, for example heat recovery from industrial catalysts, we offer the gastight welded POLYBLOC, made from

stainless steel.

This heat-exchanger is entirely welded using a microplasma process and therefore requires

no additional sealing material. Different pressure tests confirm the absolute tightness of the unit. Temperatures far over 600°C are possible depending on the selected alloy used.